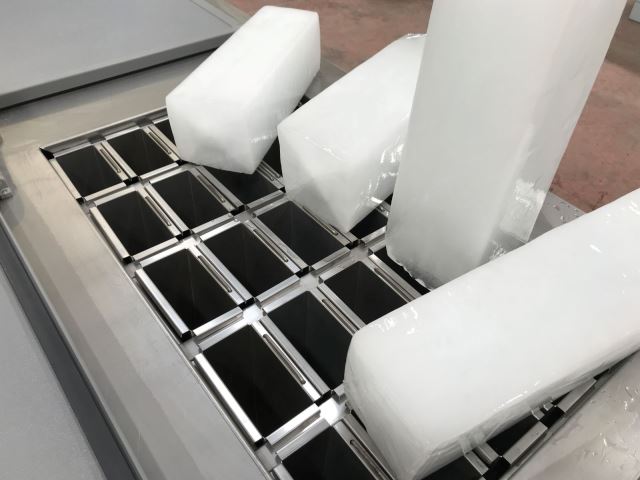

CONTAINERIZED TYPE 5000 KG/DAY BLOCK ICE MACHINE

• BRINE TYPE

| Total Ice Making Capacity: | 5000 Kg /day |

| Ice Block Amount per Shift: | 112 Blocks |

| Each Block Weight: | 15 Kg (10cm*20cm*70cm) |

| Production Time per Shift: | 7-8 Hours |

| Daily Block Production: | 336 Pcs |

| Power Supply: | 380-415 V, 3 Phase, 50-60Hz |

| Ice Temperature: | Minus 12˚C |

| Refrigerant: | Freon R404A |

| Unit Weight: | 4250 Kg |

| Unit Dimensions: | 20FT Standart Container |

| Power Consumption: | 20,40 KW/h |

| Compressor Capacity: | 30 HP |

| Condenser and Capacity: | Air Condenser / 33898 M³/H |

| Type: | 20FT Standard Isolation’s Container with Sandwich Panels |

The 5 ton per day containerized block ice machine is a high-capacity industrial cooling solution designed for large fishing ports, seafood exporters, cold chain logistics companies, meat and poultry processors, beverage factories, agricultural collection hubs, and mobile industrial cooling applications. All components are integrated inside a standard ISO container, allowing fast deployment anywhere in the world without civil construction or infrastructure investment.

With a daily output of 5,000 kg of block ice, this containerized ice plant plays a vital role in hot climate regions where refrigerated warehouses are limited or unavailable. In Africa, the Middle East, Southeast Asia, and South America, countries such as Mauritania, Senegal, Morocco, Oman, Saudi Arabia, Pakistan, Vietnam, Indonesia, Peru, and Ecuador rely on containerized block ice systems to support seafood exports and domestic food distribution.

Block ice provides long-lasting cooling and is ideal for fishing vessels, open trucks, containers, and remote markets. Fish, shrimp, tuna, meat, poultry, fruits, and vegetables remain fresh during transport and storage, reducing spoilage and increasing export value.

In addition to food and fisheries, 5 ton containerized block ice machines are widely used in concrete cooling for large infrastructure projects. Ports, bridges, dams, airports, and industrial foundations require controlled concrete temperatures, and ice is added to the mixing water to prevent cracking and improve durability.